Wave solder Tooling & Features:

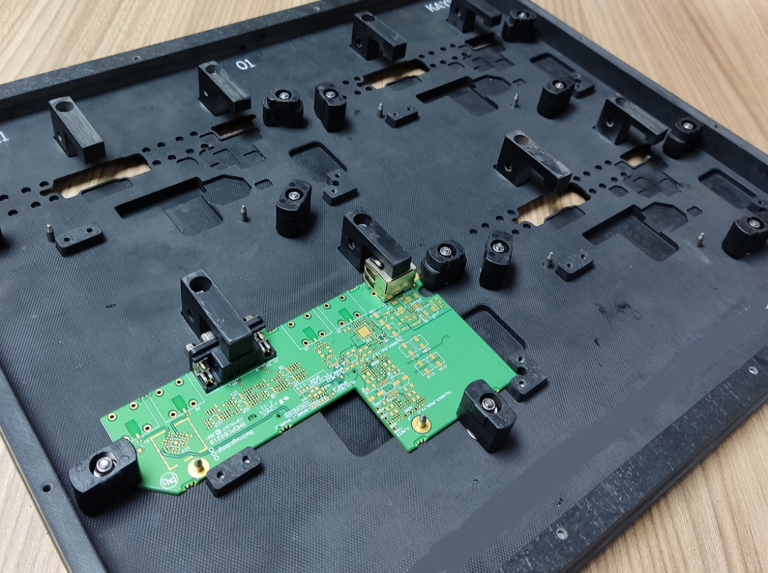

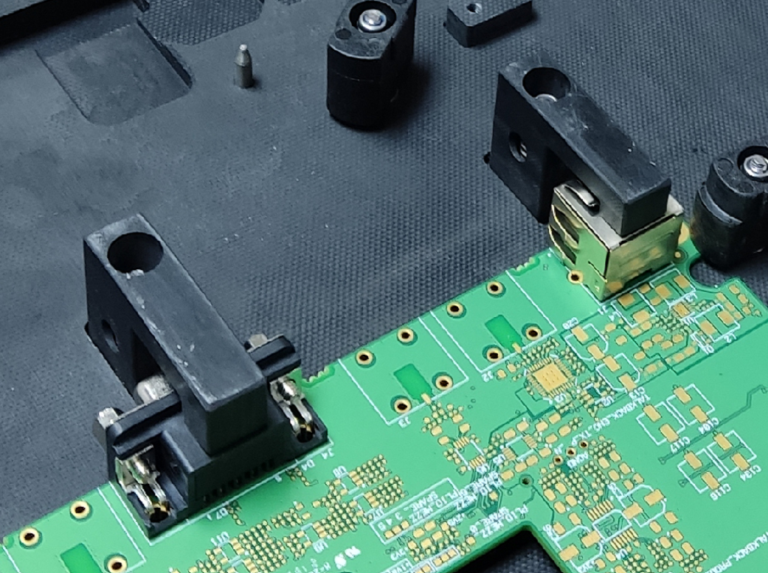

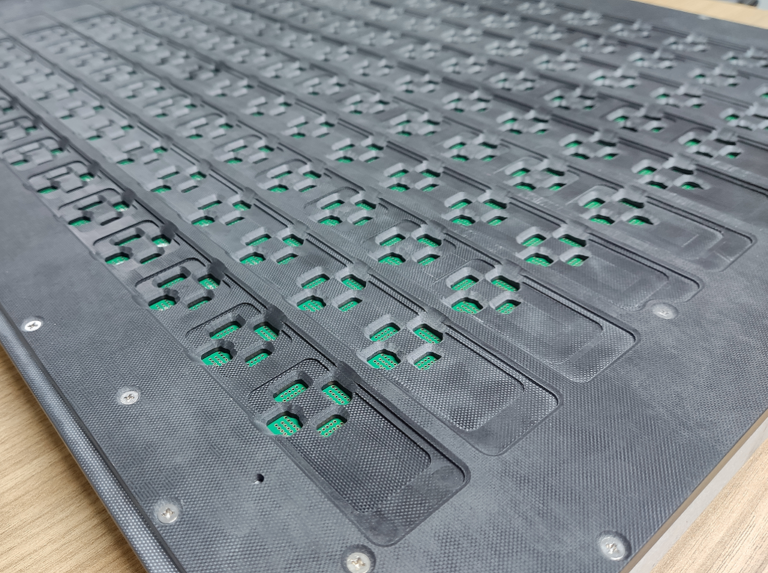

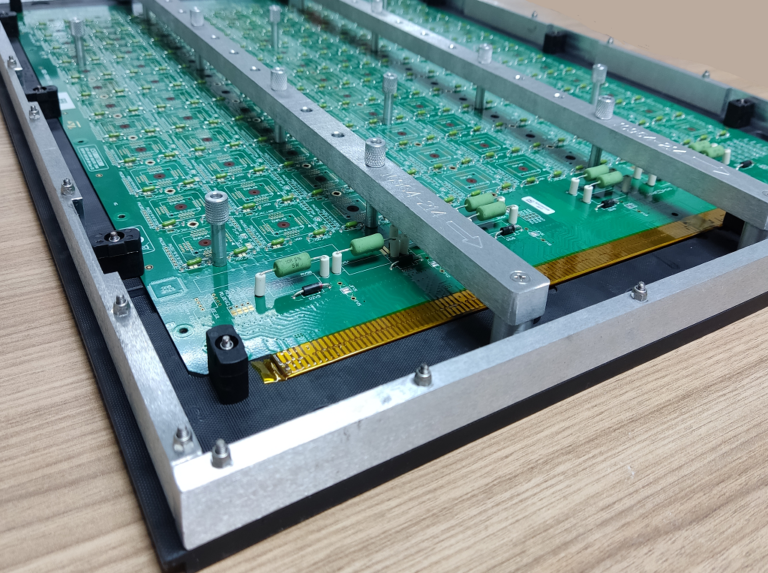

Component Relief Pockets

Relief pockets are used to mask components on the bottom-side of the PCBA, while maintaining rigidity of the pallet

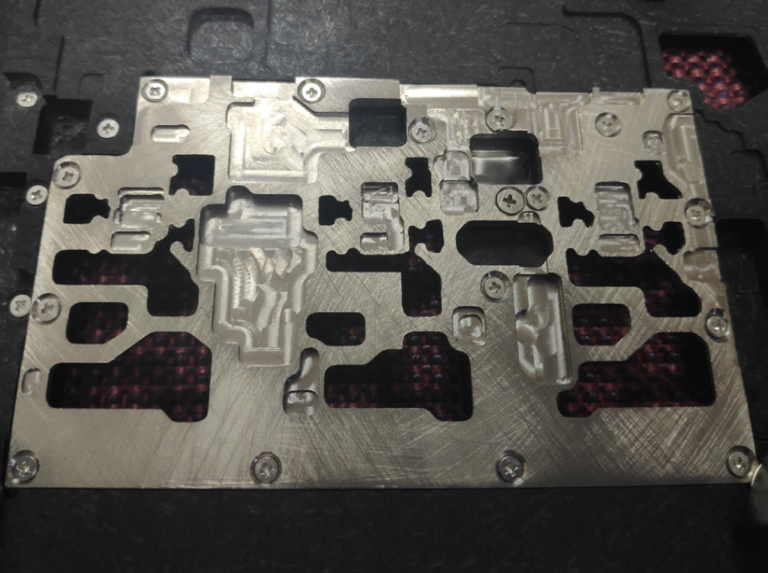

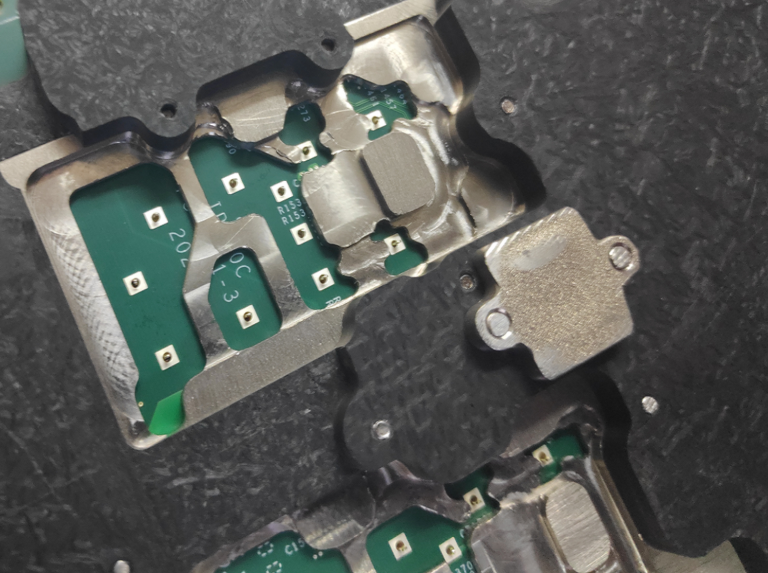

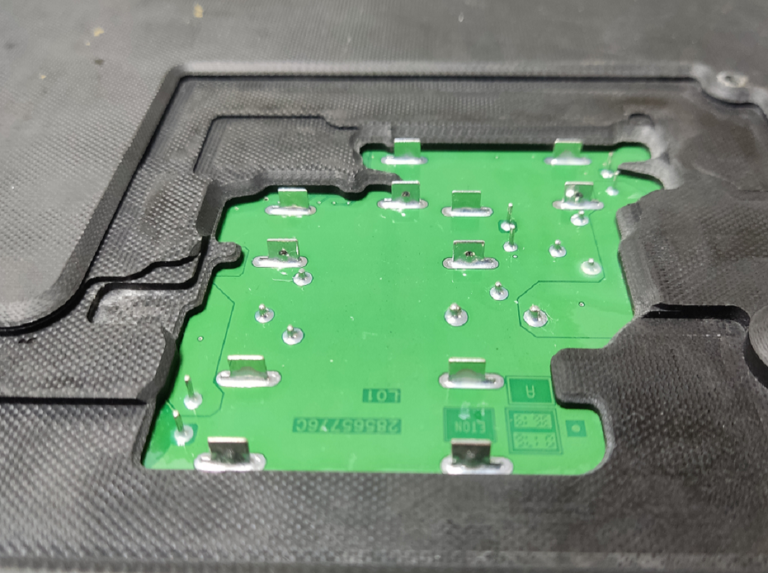

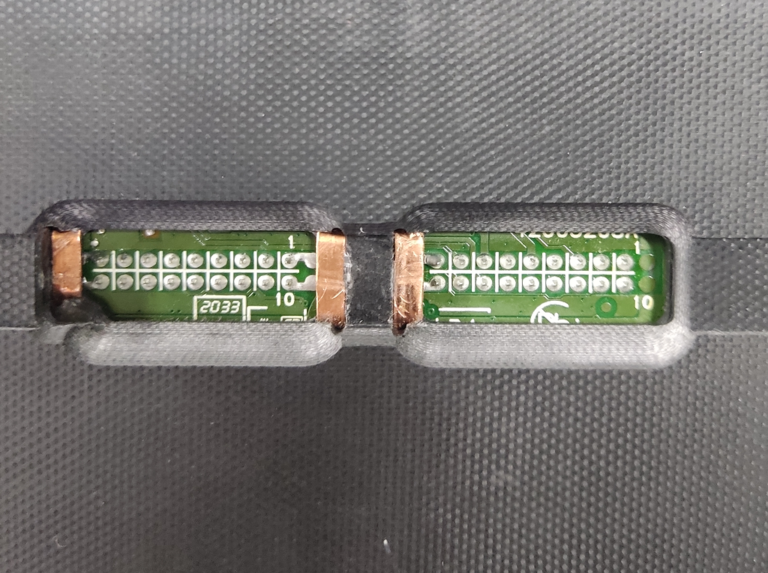

Titanium inserts

Titanium inserts enable us to expose through-hole barrels which are extremely close (<1mm) to bottom-side Surface Mount (SMT) components

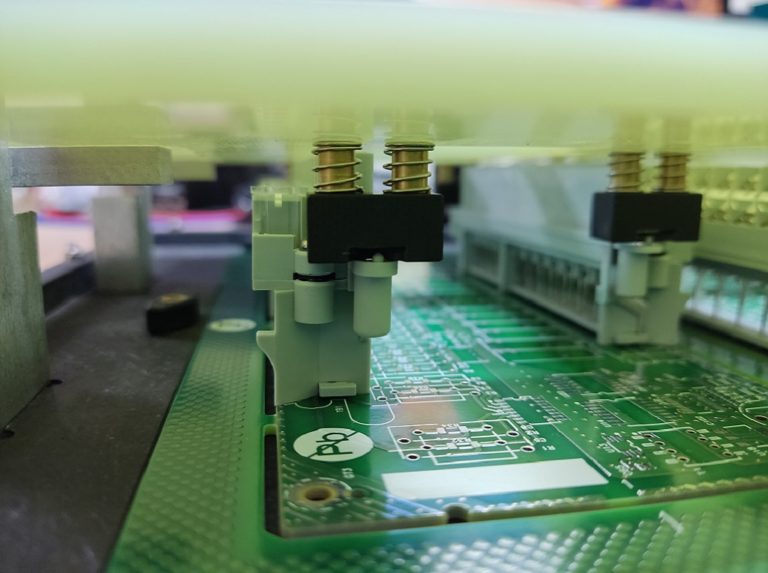

Component hold-downs

Custom clamps can be designed to hold down and align components on the PCBA.

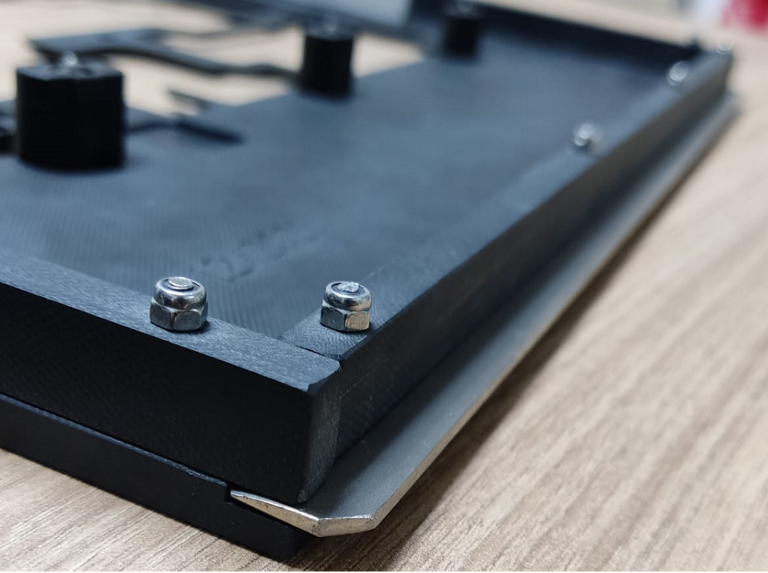

Titanium / Steel Edge-steps

Titanium edge-steps can be used to protect the pallet from wear and tear

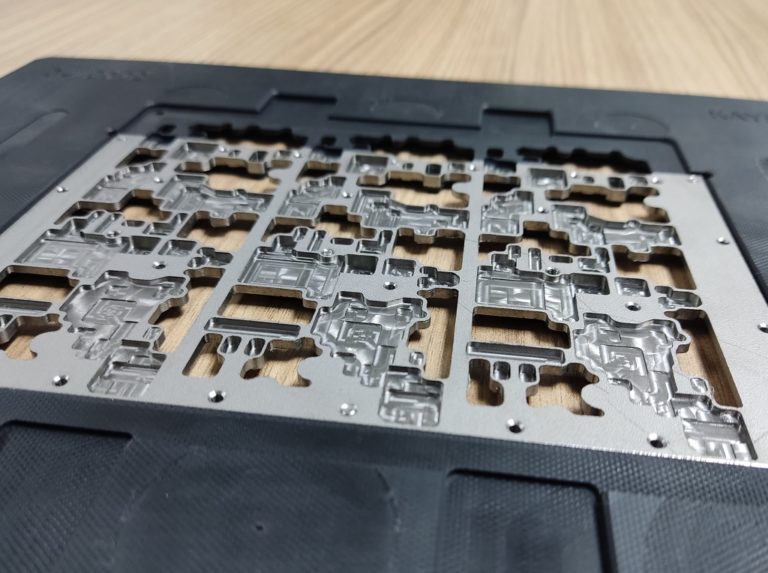

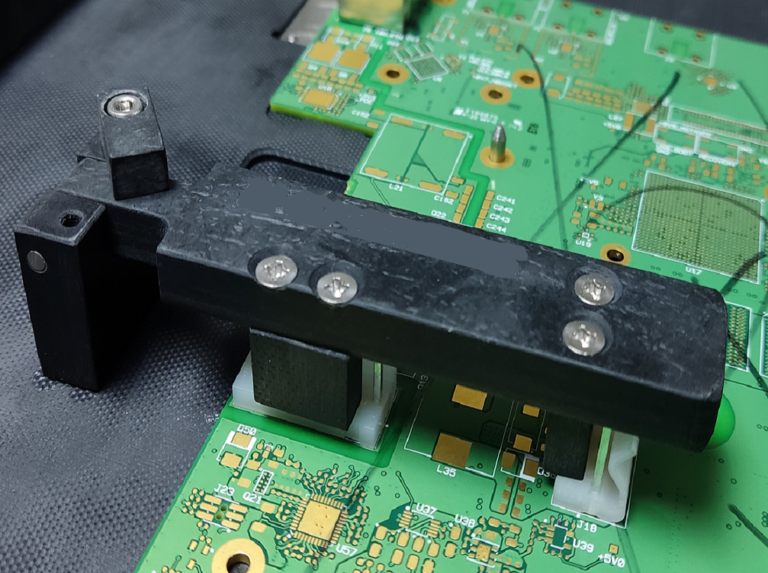

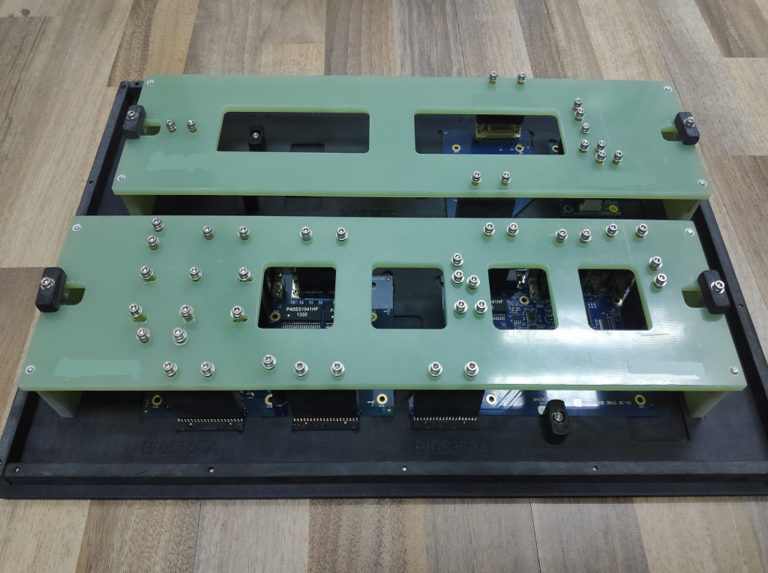

Top covers

Top covers can be designed to hold down and align multiple components on the PCBA

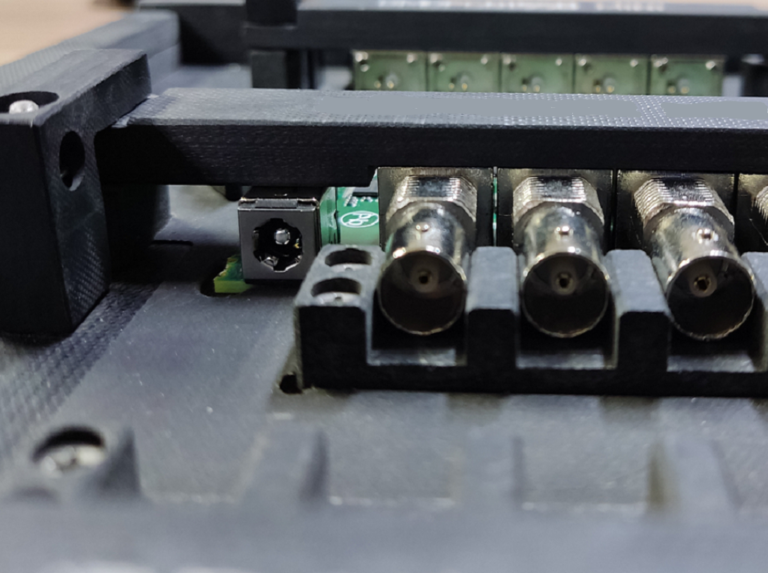

Bottom-side step-down and chamfer

Allows for better solder flow to the through-profile areas

Solder Thieves

Solder thieves are used to prevent solder bridging of multiple leads

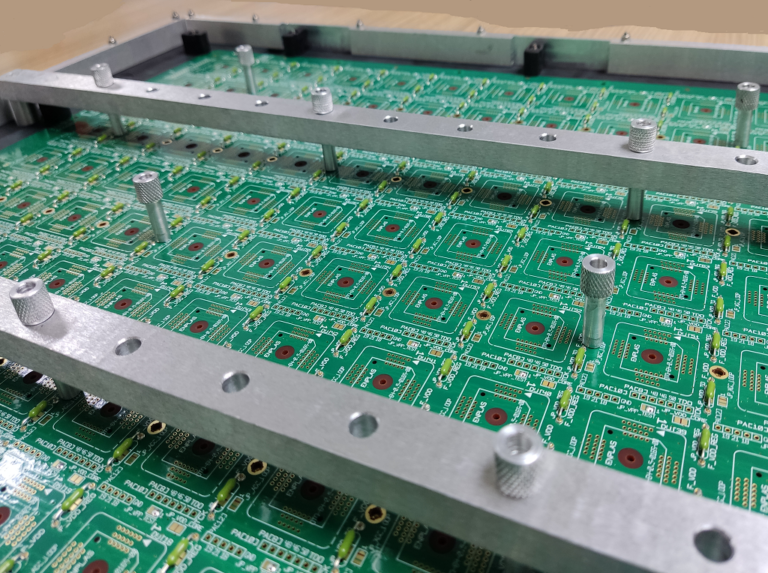

Screw inserts

Prevents large boards from warping during the pre-heat and wave-solder processes.

Adjustable Carriers

Universal pallets can accomodate various PCBAs with different sizes